UTQA Offers the below Inspections

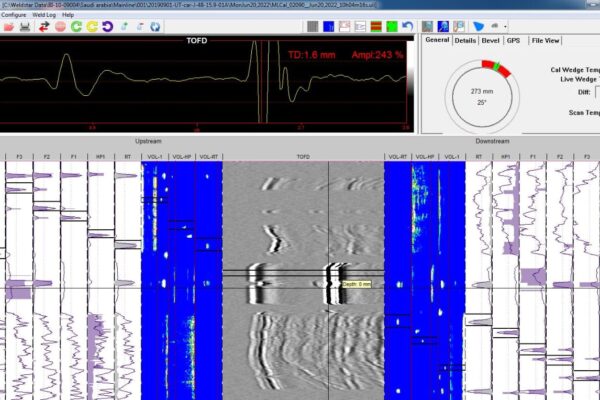

Automated Ultrasonic Testing – Pipelines

- UTQA provides AUT for Pipeline Testing with Weldstar in Pipeline girthweld inspection system from GE Inspections Technologies, Combination of focused Phased Array and ToFD.

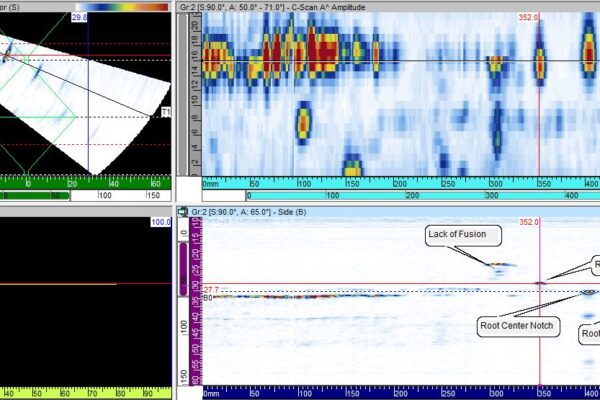

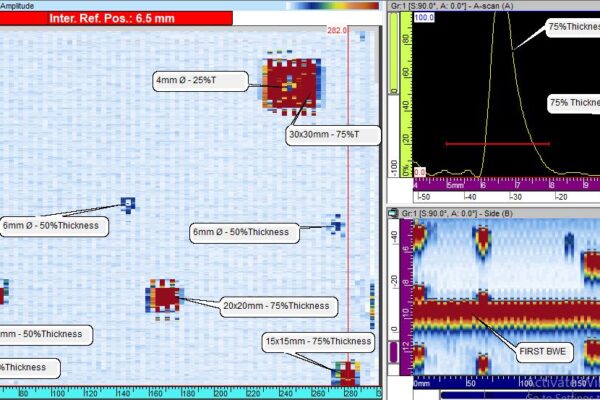

Phased Array Ultrasonic Testing

- UTQA provides ultrasonic phased array testing to inspect welds of process equipment, piping and structures. Ultrasonic phased arrays offer very reliable detection and sizing capabilities along with a permanent record of ultrasonic inspection lieu of Radiographic Testing.

Time of Flight Diffraction Testing

- UTQA provides ultrasonic ToFD services to inspect welds of process vessels and piping. ToFD is a reliable and quickly advancing ultrasonic technique with good sizing capabilities and higher inspection speed.

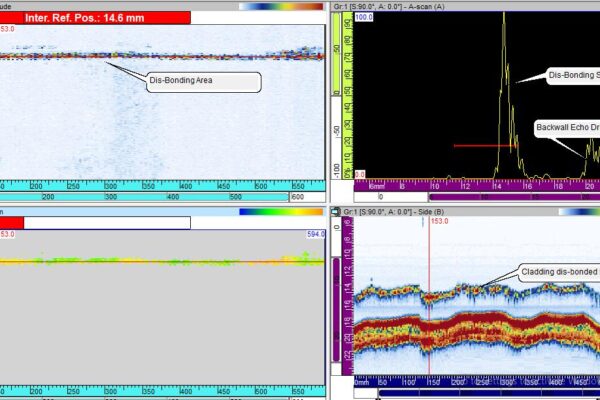

Corrosion Mapping / Clad Overlay Mapping using X-Y Scanner

- UTQA provides X-Y scanner for corrosion mapping/Weld Mapping for production piping, plant piping, storage tanks and equipment.

Short Range Ultrasonic Testing of Tank Annular Plates

- Short Range Ultrasound (SRUT) inspection of the outer tank bottom annular ring plates provides a testing method that is sensitive to top and underside deterioration. It can access critical locations on the tank bottom annular plates while the tank is in service.

Remote Videoscopes Inspection

- Remote Videoscope Inspection services for visual inspection of limited access areas such as heat exchanges, pressure vessels and piping.

Heat Exchanger Tube Inspection – For various Tube Materials as below –

- Eddy Current Testing (ET) – for non-ferromagnetic tubes.

- Internal Rotary Inspection Systems (IRIS) – any material, accurate wall thickness measurements.

- Magnetic Flux Leakage Testing (MFLT) – for ferromagnetic and Finfan cooler tubes.

- Remote Field Eddy Current Testing (RFT) – for ferromagnetic tubes.

- Saturated Eddy Current Testing (ET) – for ferrous tubes.

Magnetic Flux Leakage – Tank Bottom Floor Plates

- Combination of two techniques; Magnetic Flux Leakage (MFL) and Ultrasonic Testing to provide completed Floor Map Corrosion Inspection of tank bottom floor can be detected and those corroded areas can be repaired as per API 653.

Conventional NDT Testing

- Ultrasonic Testing – Thickness Gauging/Grid Scanning, Weld Scanning, Lamination and Cladded Plate Scans.

- Magnetic Particle Testing – Visible and Florescent

- Dye Penetrant Testing – Visible and Florescent

![PHOTO-2022-05-24-15-06-21[1] PHOTO-2022-05-24-15-06-21[1]](http://utqa-sa.com/wp-content/uploads/2022/08/PHOTO-2022-05-24-15-06-211-600x400.jpg)